Fire-resistant electrical tape is versatile and can be used in numerous applications. In industrial environments, where heavy machinery and high electrical loads are common, the risk of electrical fires increases. Using fire-resistant tape to insulate wires and connections can substantially mitigate this risk. It is particularly beneficial in high-temperature applications, such as motors, transformers, and circuit boards.

Uses for self-amalgamating tape

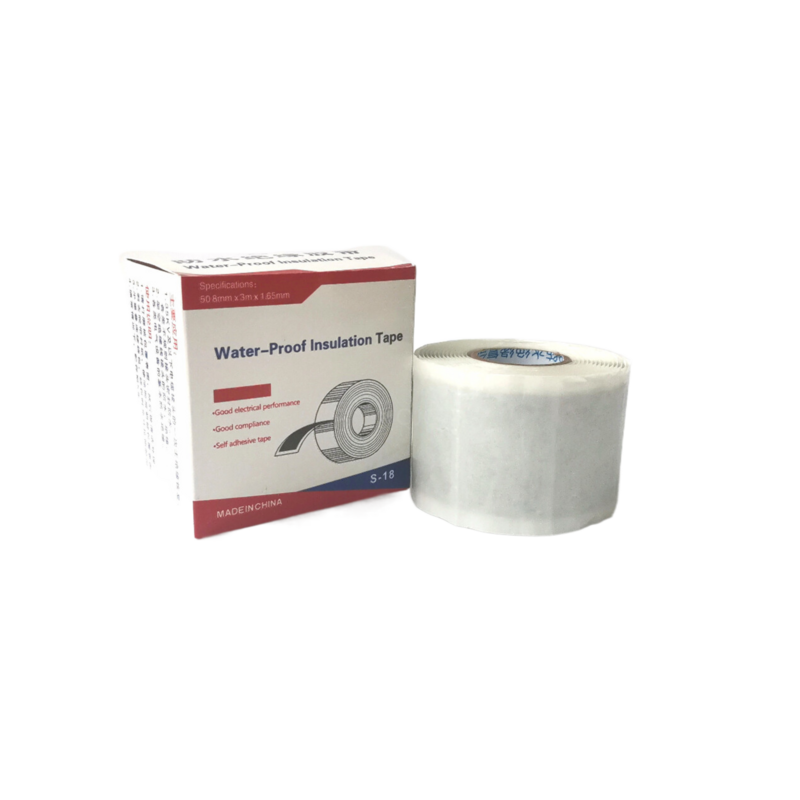

High voltage busbar insulation tape is specifically designed to withstand elevated voltage conditions. It serves as a barrier that isolates electrical conductors and protects against external factors such as moisture, dust, and chemical exposure.

Plastic wiring loom wraps are generally more rigid and durable, making them ideal for protecting wires in areas where they are likely to be exposed to moisture or physical damage. Fabric wraps, on the other hand, are more flexible and breathable, allowing for better airflow and heat dissipation around the wires.

black tack butyl. It comes in a convenient tube that allows you to apply the adhesive directly to the surface you want to bond. The tube is designed with a nozzle that allows you to control the flow of the adhesive, ensuring that you get just the right amount for your project.

black tack butyl. It comes in a convenient tube that allows you to apply the adhesive directly to the surface you want to bond. The tube is designed with a nozzle that allows you to control the flow of the adhesive, ensuring that you get just the right amount for your project.Natural Rubber

The 4 x 5 size of Flex Tape Black is particularly advantageous. The width provides a broad surface area for applications, allowing you to cover larger gaps or tears with just one piece. This is particularly useful for quick fixes around the house, from sealing leaks in pipes or roofs to fixing torn screens or tarps.

rubber seal strip. In addition, rubber seal strips can also help to reduce drafts and improve indoor air quality by preventing the entry of outdoor pollutants.

Polyethylene, polyester, and polyimide are three different types of carrier materials used in adhesive tapes, each with its own advantages and characteristics.

The head is usually Philips or Pozidriv, allowing for better torque control during installation and reducing the risk of cam-out, which is the premature disengagement of the screwdriver from the screw head The head is usually Philips or Pozidriv, allowing for better torque control during installation and reducing the risk of cam-out, which is the premature disengagement of the screwdriver from the screw head

The head is usually Philips or Pozidriv, allowing for better torque control during installation and reducing the risk of cam-out, which is the premature disengagement of the screwdriver from the screw head The head is usually Philips or Pozidriv, allowing for better torque control during installation and reducing the risk of cam-out, which is the premature disengagement of the screwdriver from the screw head Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments

Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments Its resistance to abrasion, chemicals, and temperature fluctuations makes it suitable for use in both indoor and outdoor environments